Equipment - Steel Door and Frame Welders

Hollow Metal Door Industry Welders

In 1960, LORS Machinery sold its first welder to the Commercial Hollow Metal Door Industry. Since then, LORS has become the leader in Resistance Welding for the Hollow Metal Door Industry, supporting shops from 25 doors per day to over 2,000 doors per day. Today, RWC is your Resistance Welding Support, picking up where LORS left off. We have over 1,000 welders worldwide in the USA, Canada, Mexico, Korea and the Middle East, to cut welding costs and increase productivity. We offer many additional automated systems as well.

Door Welders

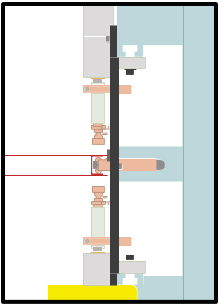

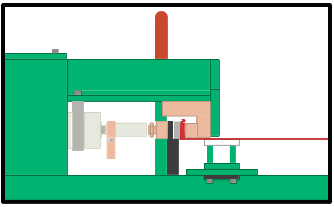

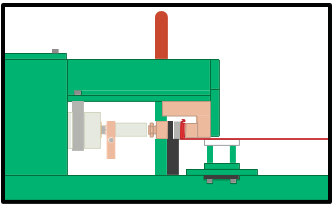

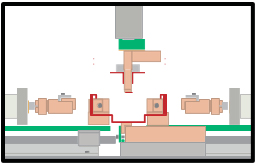

End Channel Projection Welder ECPW1209x4 (Similar to Model 858)

|

|

End Channel Welder featuring three (3) transformers and nine (9) reciprocating-type weld guns, 120 KVA rated. Machine is set up with a microprocessor control with cascade firing and automatic width select. Other configurations are also available from 3-6" centers up to 48" wide. |

|

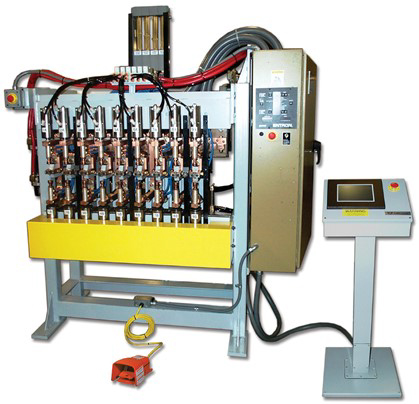

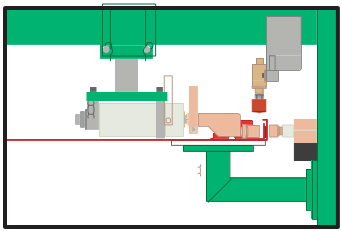

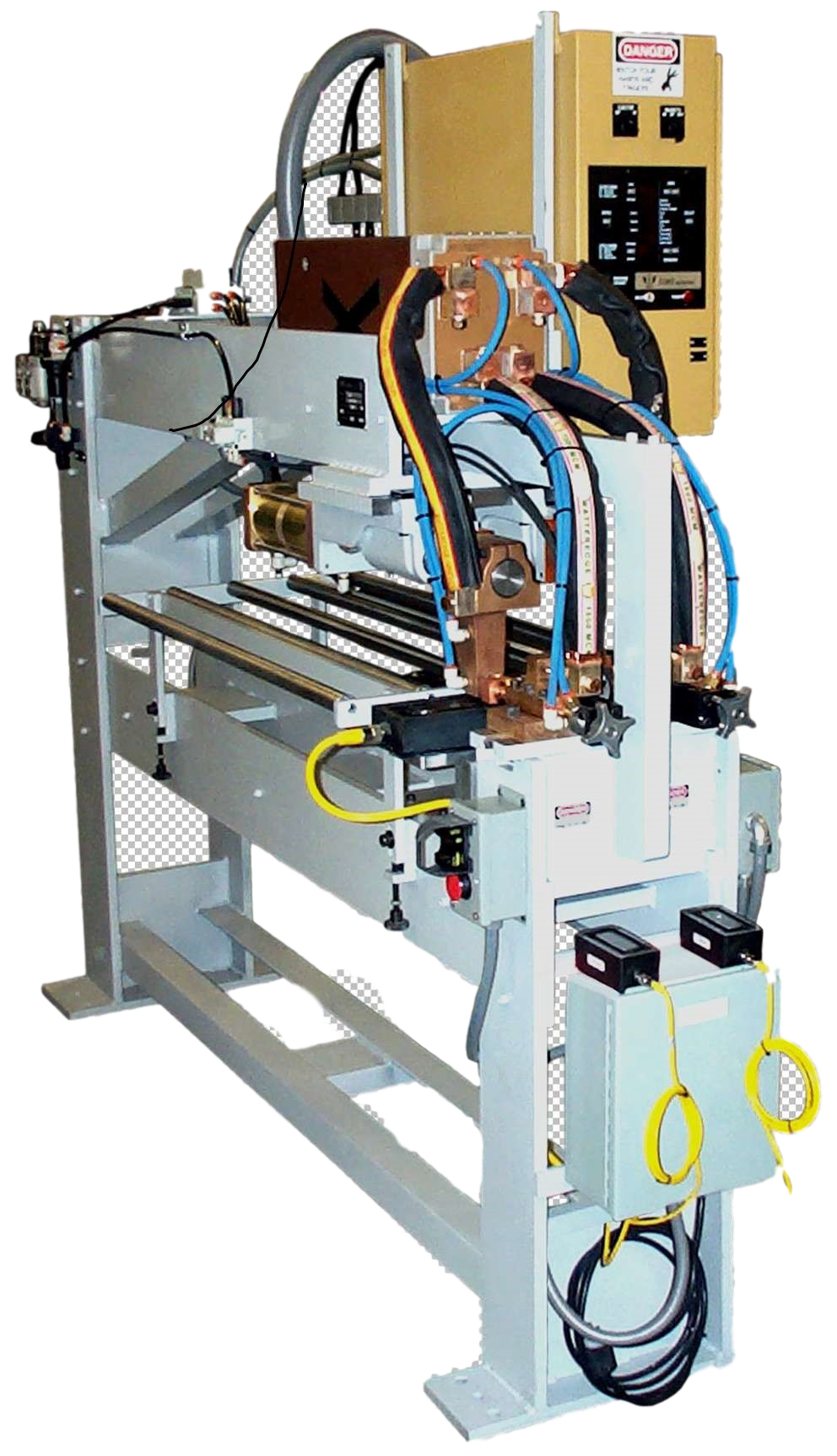

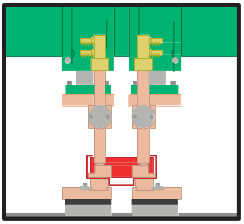

End Channel Spot Welder ECSW1206x4 (Similar to Model 734)

|

|

End Channel Welder featuring a single transformer rated 70 KVA and six (6) reciprocating-type weld guns on 4" centers that reach inside the end channel. This welder is capable of welding end channels on both narrow and wide doors. Long-life CCNB alloy weld dies minimize marking on exterior surface. Other configurations are also available from 3-6" centers up to 48" door widths. |

|

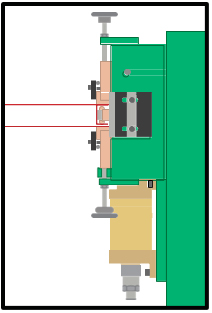

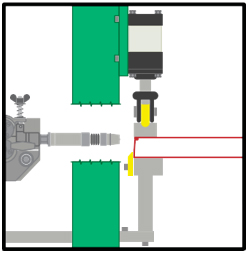

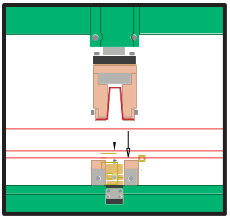

Hinge Reinforcement Welder DHRW1202A (Similar to Model 145)

|

|

Horizontal dual gun projection welder, 120 KVA rated. Designed for projection welding hinge reinforcements to doors. Horizontal design permits welding with door in the flat position, eliminating need to stand door on edge, and reduces handling. Dual weld guns may be operated individually in a gun sequence mode, or together to permit welding both tabs of a single hinge reinforcement location. Pneumatic hold-down pads are provided to maintain flatness of door during welding. |

|

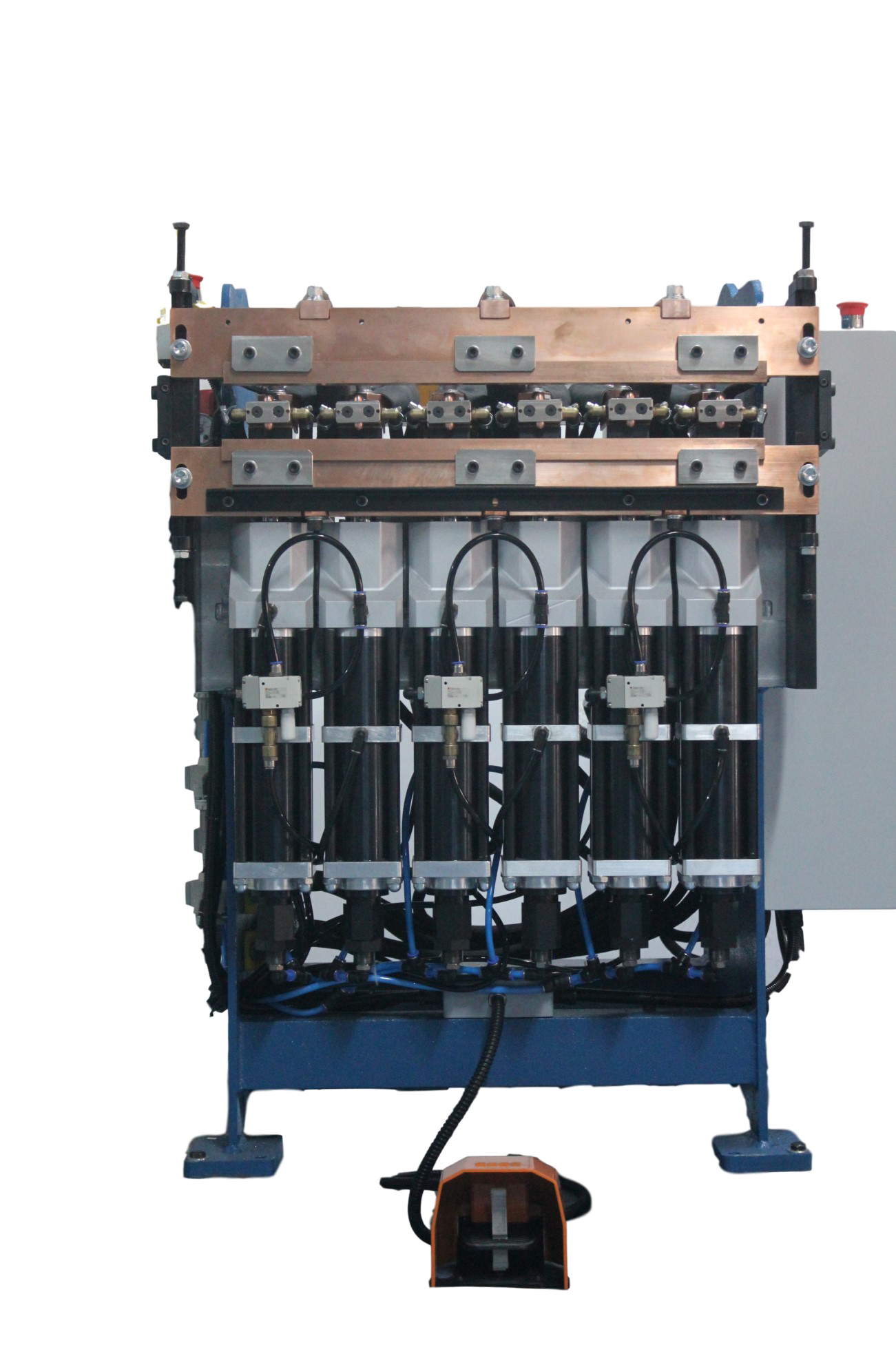

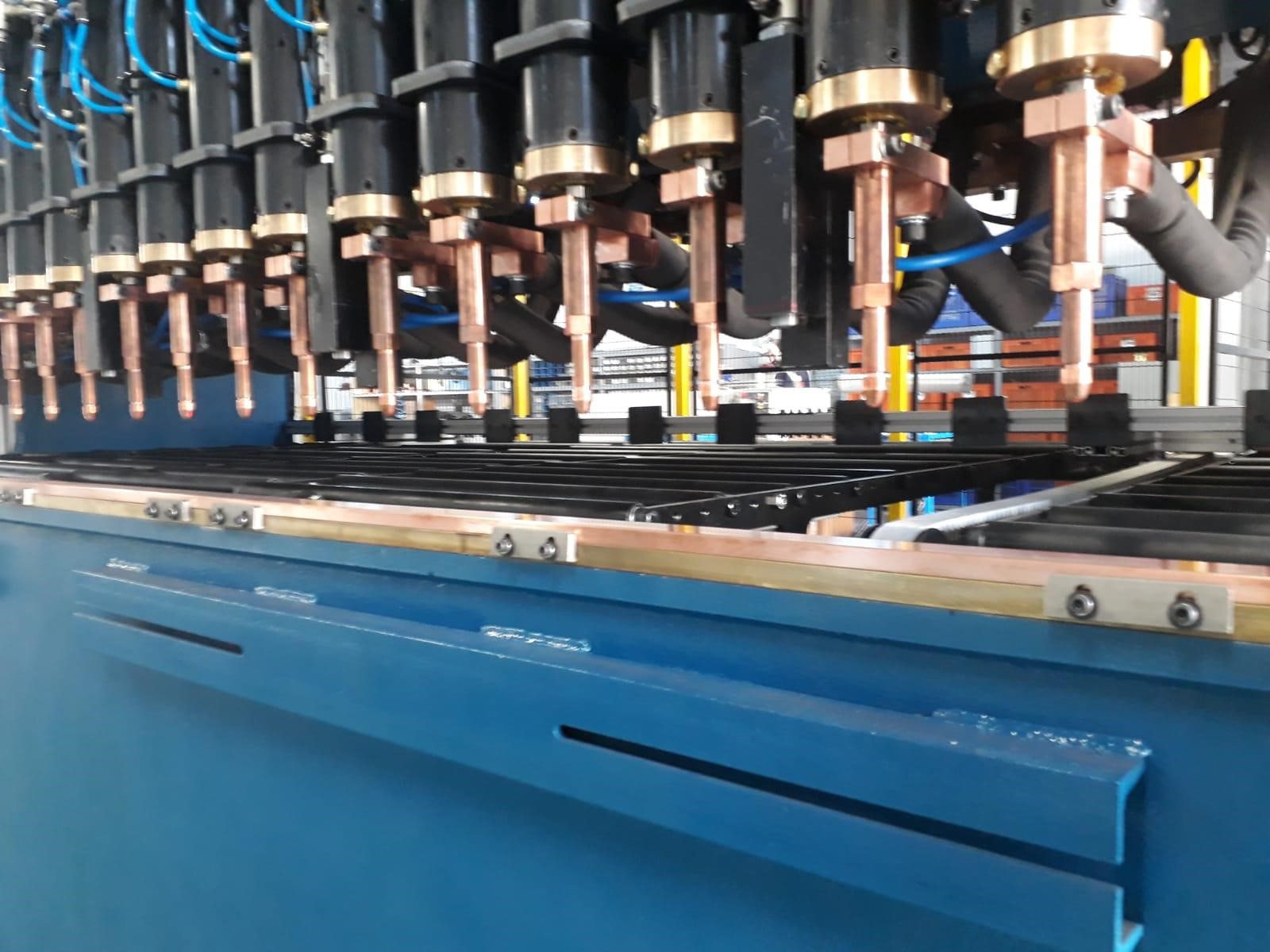

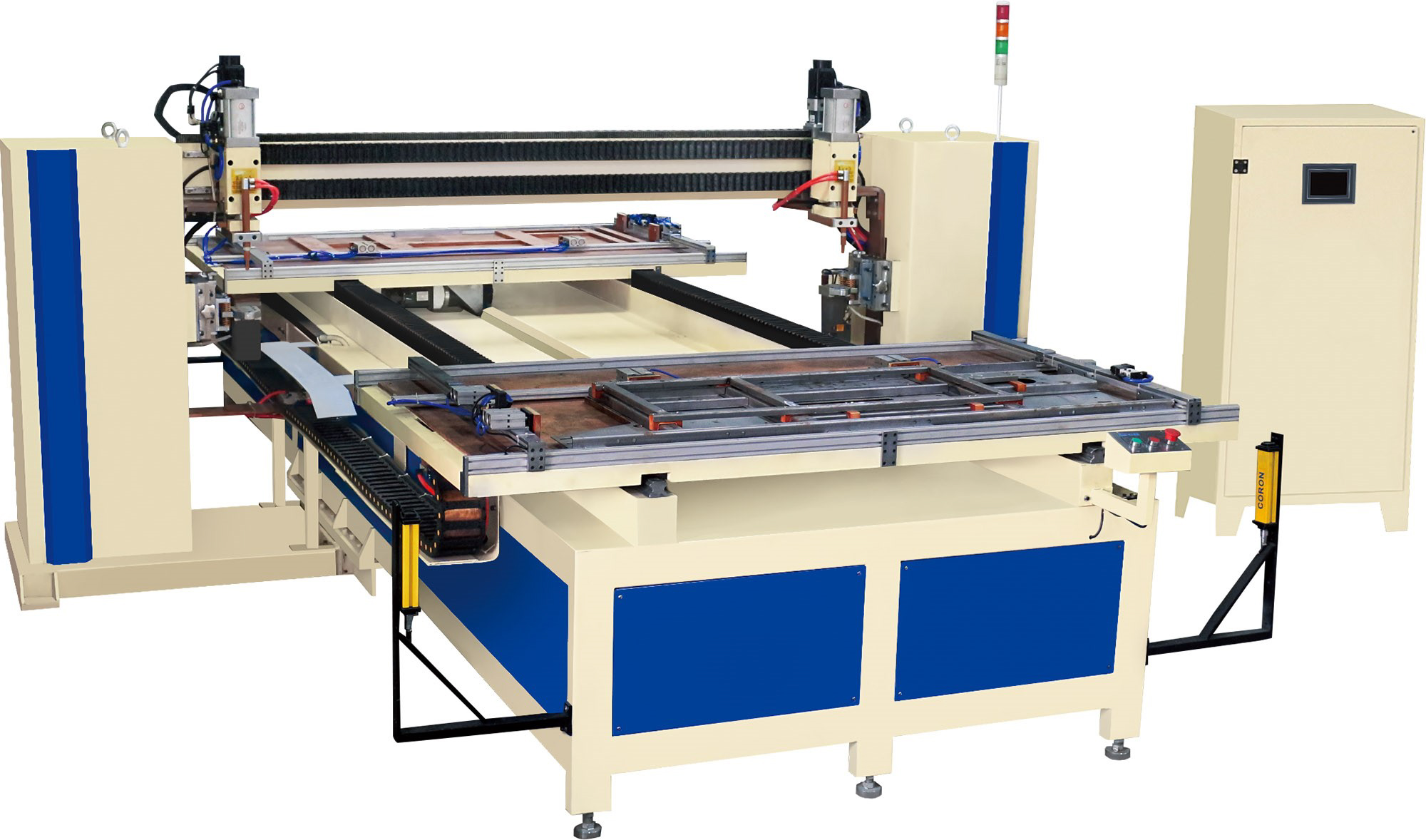

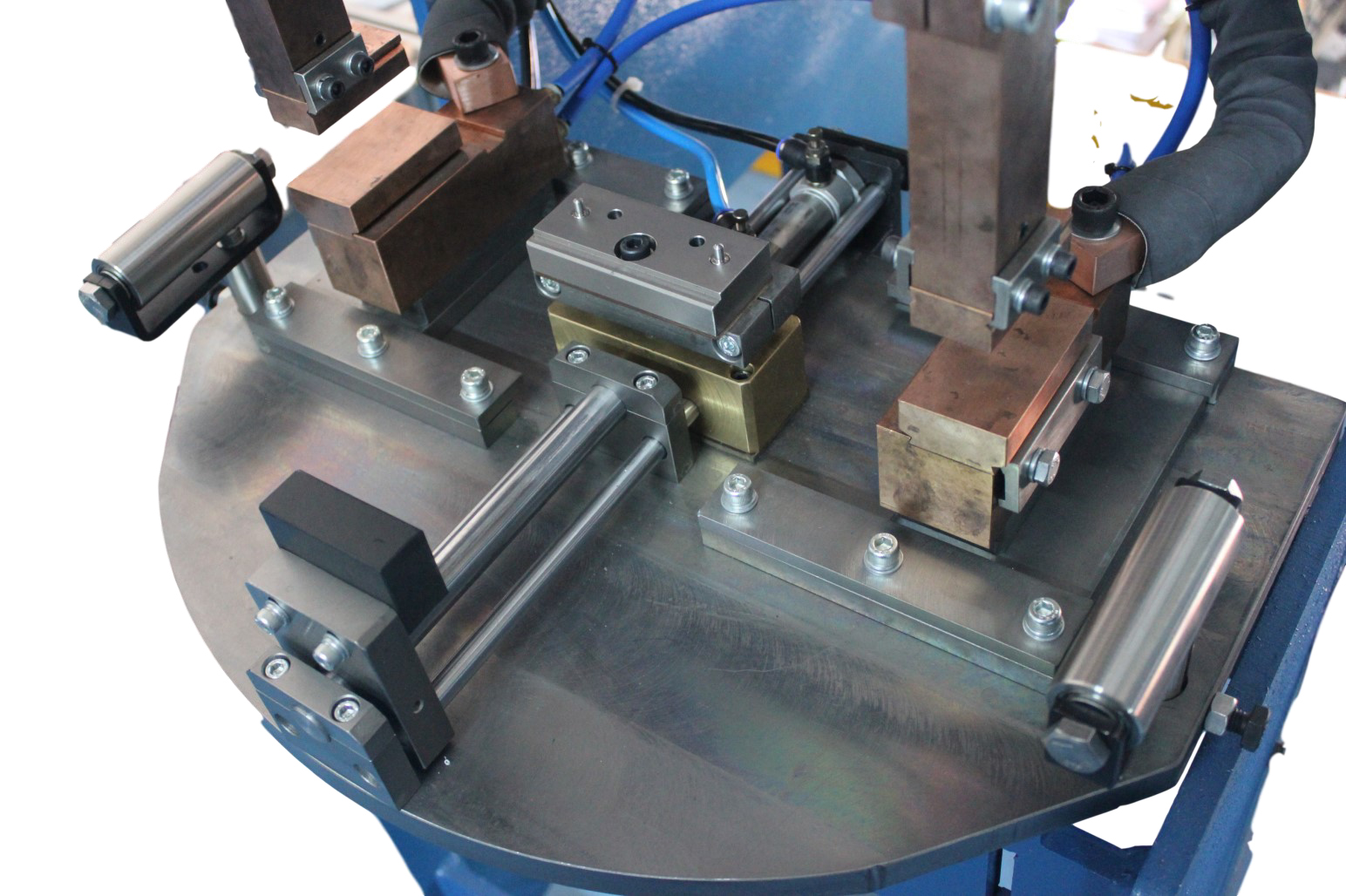

Door Stiffener Welders

We have a version to suit your needs

Multihead spot welders, from manually-loaded pushed the welder, to our fully-automated solutions. Depending on your needs, we can move the door through the welder lengthwise, or for the high-volume shops, width-wise with up to 32 weld heads. All of our welders are available with automated back stops for easy positioning or full CNC options for the ultimate in flexibility. This option will weld stiffeners as well as window frames and other reinforcement plates. Weld one while the second table is being loaded. Our CNC welder is available in AC or MFDC for reduced marking on stainless steel.

|

|

|

|

Door Hinge and Lockbox Welder DHPW1AO060A (Similar to Model 658 and in function to 856)

|

|

Horizontal single gun spot or projection welder, 60 KVA rated. Designed for projection or spot welding both hinge and lock box reinforcement to doors. Horizontal design permits welding with door in the flat position, eliminating need to stand the door on edge. Unlike the DHRW08502AX welder, this open-style welder provides easy access to locate the door and hinge or lock box. A pneumatic hold down pad is also provided. |

|

Door Hinge Welder DHPW2AO110R (Similar to Model 145/607)

|

|

Horizontal dual gun projection welder, 120 KVA rated. Designed for projection welding both hinge and lock box reinforcements to doors. Horizontal design permits welding with door in the flat position, eliminating need to stand door on edge, and reduces handling. Dual weld guns may be operated individually in a gun sequence mode, or together to permit welding both tabs of a single hinge reinforcement location. Pneumatic hold-down pads are provided to maintain flatness of door during welding. The weld control can be set high, as shown, or below conveyor. |

|

GMAW Seam Welder DESW120M

|

|

This third-generation seam welder welds longitudinal seams on door edges. Can be set up for lock joint or overlap joint. The welder is user-configurable to continuous weld or stitch weld. Sensors automatically stop the welding at openings with user-defined starts and stops. Roller tables provide easy positioning of door, and pneumatically-operated water-cooled clamps secure door during welding and transfer welding heat away from door. We will weld CRS, galvanized, and stainless steel doors. |

|

Frame Welders

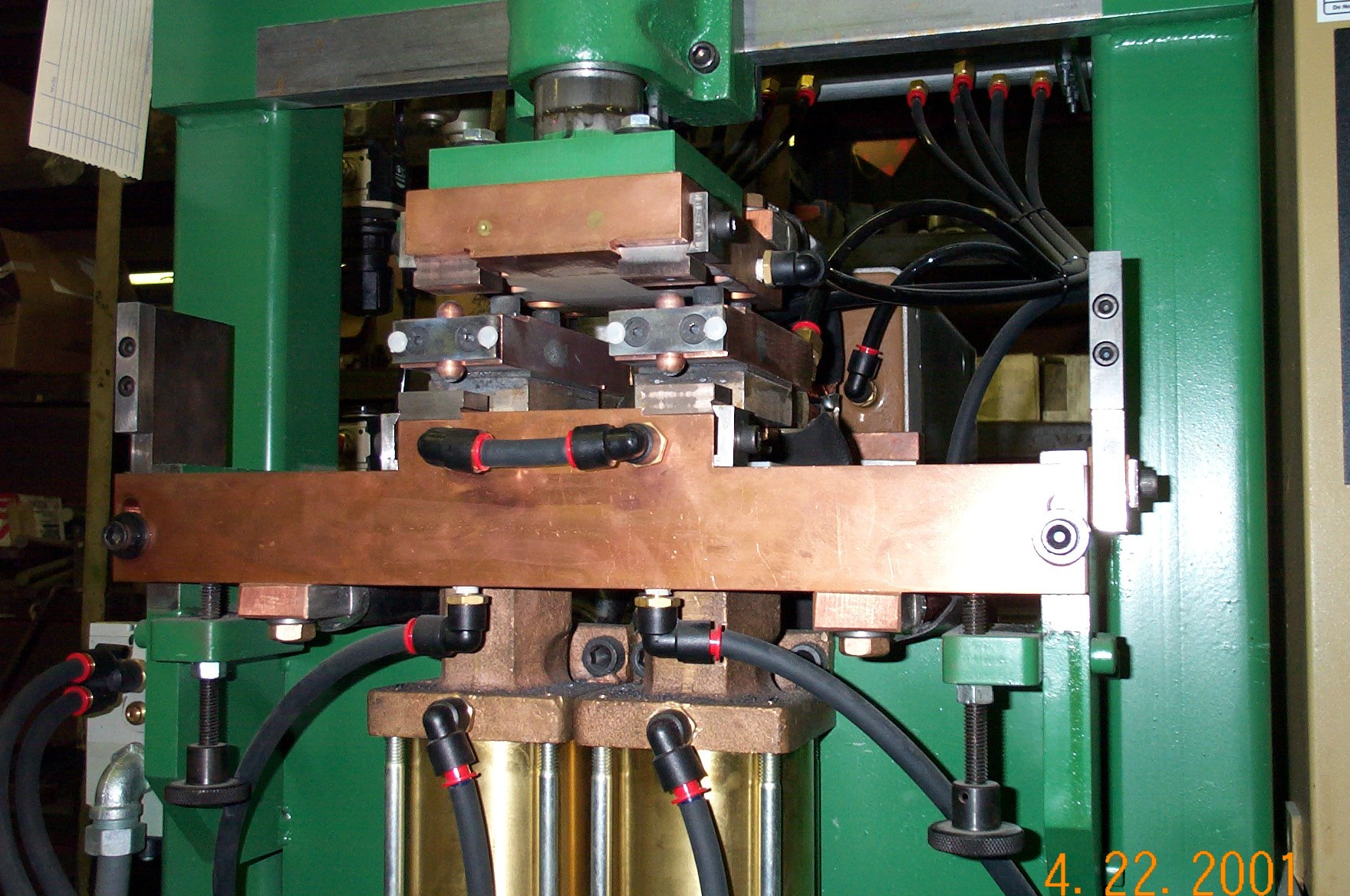

Hinge Reinforcement Welder FRW1x1202AH (Similar to Model 771)

|

|

Dual gun projection welder, 120 KVA rated. Designed for projection-welding hinge reinforcement to jambs, one hinge per sequence. Dual gun design assures correct weld force on both ends of hinge reinforcement and eliminates weld force distribution problems common to single-gun projection welders. Welder features a pneumatically-operated jamb clamp and pin fixture with time delay to lower pin for transfer of jamb to subsequent position for welding. Includes an anti-tie-down dual palm switch initiation and a solid-state welding control with up to 32 weld schedule capacity. |

|

Hinge Reinforcement Welder FRW1A1202AH (Similar to Model 771)

|

A single-head press welder adapted to the proven fixturing used in the Model 771, but in a lower-cost platform complete with a 32-schedule microprocessor weld control. The upper weld electrodes are mounted on a load-balancing holder to ensure class A weld quality every time. |

|

Pressure Plate Welder FAW0852PP (Similar to Model 790

|

|

Dual station welder, 85 KVA rated. Station one (1) is for welding pressure plate to jamb single hit projection weld. Station two (2) is for welding gussets to end of jamb with dual equalizing guns. Both stations have new CCNB high-performance copper alloy electrodes for easy leak-free replacement. Includes an anti-tie-down dual palm switch initiation and a solid-state welding control with up to 64 weld schedule capacity. Control shown with optional magnetic circuit breaker. |

|

Stud & Floor Anchor Welder FAW0852AFA (Similar to Model 869)

|

|

Dual gun projection welder, 85 KVA rated. This welder is designed for welding stud and floor anchors to door frames. Features two adjustable retraction stroke ramtype weld guns and replaceable weld dies. The bottom weld dies are mounted on left and right sliding platforms. Includse a set of front and rear guiding wheels for jamb positioning. Features an anti-tie-down dual palm switch initiation and a solid-state welding control with up to 64 weld schedule capability. Control shown with optional magnetic circuit breaker. |

|

Anchor & Plumb Bracket Welder (Similar to Model 871)

|

|

Single gun projection welder, 85 KVA rated. This welder is designed to weld anchor and plumb brackets. Includes a set of air-operated lift cylinders, parts locator and guides for quick change fixturing. Includes an anti-tie-down dual palm switch initiation and a solid-state welding control with up to 300 weld schedule capability. Control shown with optional magnetic circuit breaker. |

|

Other Designs

|

Window Frame Welder |

Small End Channel Spot Welder |

|

|

Higher Volume Hinge and Lockbox Reinforcement Welders |

|

|

All welders contain user-friendly weld controls with an unparalleled warranty. Other weld controls are available for even more process control and retain our best-in-class warranty.